Mechanical Capability

With USI's leading capabilities in product design, manufacturing services and modularization in addition to Memtech's mechanical competencies in mold-fabrications, plastic injections, silicone rubber moldings, liquid-silicone-rubber injections & hybrid material co-moldings etc., both business and technical cooperation will enhance USI's supply chain dynamics and raise its overall competitiveness.

Memtech is a well-established company with strong process design and technical advantage focusing on precision mold processing and mechanical component manufacturing in automotive, consumer electronics, industrial and medical industry.

What is CE-MDD?

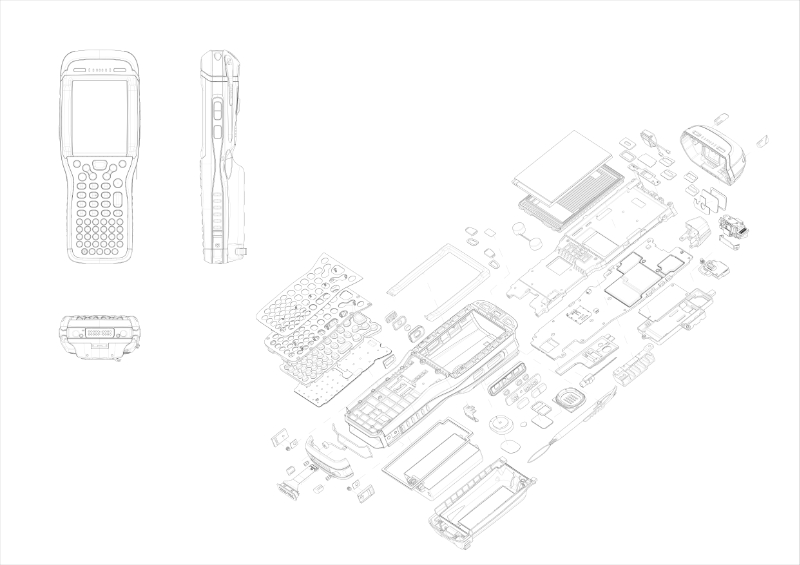

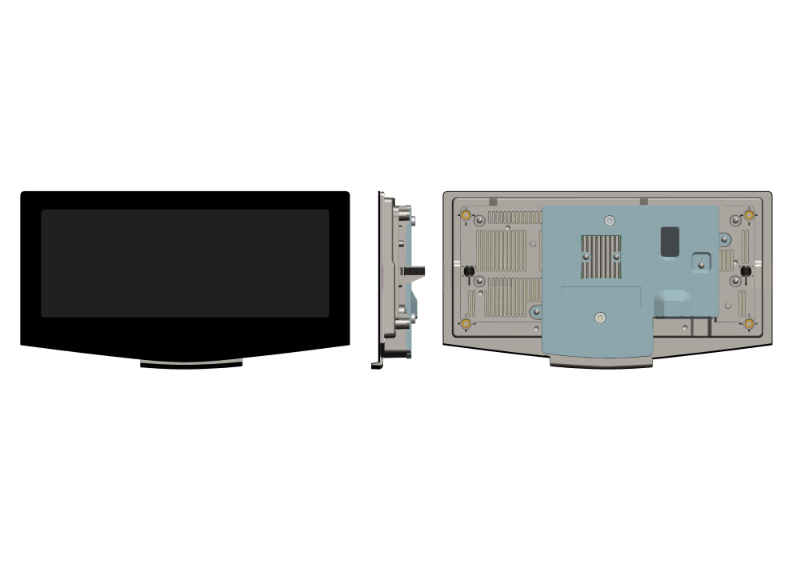

In USI, CE-MDD plays a central role in the development of system products that include Vehicle Computer, Specific Application Devices, Smart Handheld Devices, Port Replicator, Point of Sales (POS), AES Pen, Servers, Car Display Systems, etc.). CE-MDD serves as the Centralized Mechanical Resources Provider for system product developments. With this format, we can foster broad product design experience and easily synchronize various product developments under a coherent management system. Our development strategy is to build mechanical design capability from peripheral parts or products as the first stage to gain confidence in sister product. Through this practice, we apply entire product design and manufacturing knowledge including industrial design, mechanical design, material selection, tooling design, component manufacturing processes, and even simulation results to assist product development.

CE-MDD

In USI, CE-MDD plays a central role in the development of system products that include Vehicle Computer, Specific Application Devices, Smart Handheld Devices, Port Replicator, Point of Sales (POS), AES Pen, Servers, Car Display Systems, etc.). CE-MDD serves as the Centralized Mechanical Resources Provider for system product developments. With this format, we can foster broad product design experience and easily synchronize various product developments under a coherent management system. Our development strategy is to build mechanical design capability from peripheral parts or products as the first stage to gain confidence in sister product. Through this practice, we apply entire product design and manufacturing knowledge including industrial design, mechanical design, material selection, tooling design, component manufacturing processes, and even simulation results to assist product development.

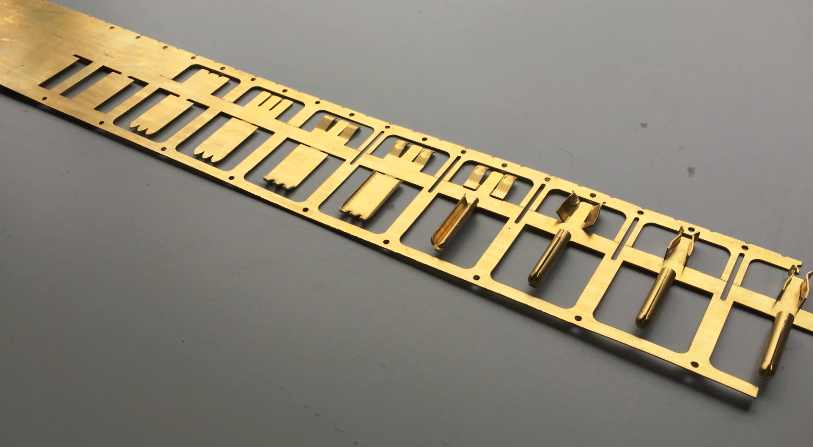

Tooling Development

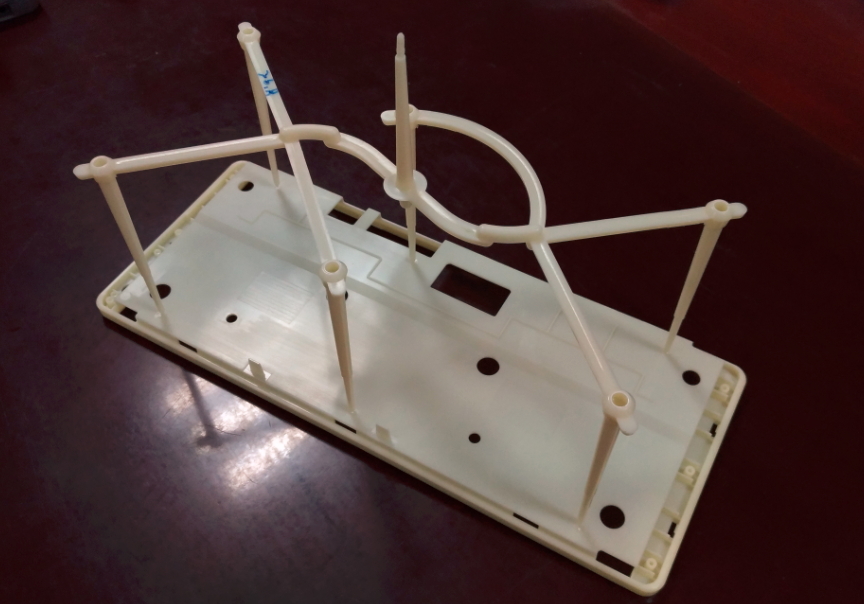

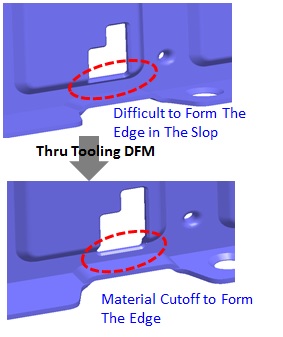

In general, tooling reduces the overall manufacturing cost of a product by producing acceptable parts at lowest cost. Thus, the tooling design will affect the quality of product design. Basically, we focus on Stamping dies and Plastics Injection dies since these two types of dies are major component manufacturing processes for our products. However, we also have experience in other types of component using Die Casting, Metal Injection Molding, etc. processes, which are covered by our tooling design team as well. In order to well manage the quality of tooling development, we have dedicated tooling engineers stationing in both China and Taiwan.

USI’s Tooling Dept. contains three territories (i.e. Tooling Development, Secondary Processes Verification and Material Application Study). We ensure tooling right at the first time to avoid costly modification cycles. Plastics injection dies section covers double injection (plastics + rubber, plastics + metal), insert molding (plastics + sheet metal + magnet). On the other hand, stamping dies section covers progressive dies and transfer dies. We convey the interface with our mechanical suppliers to extend our coverage. Consistently deliver quality tooling by DFM review to optimize mechanical design practices. Under current coverage (tooling + 2nd processes involvement + material application study), engineers can develop and share ideas, for boosting creativity, shortening the tooling manufacturing process and providing optimized solutions (component finishing and proper material adoption) to overcome product design challenges. Simultaneously, higher design efficiency drives higher product quality through streamlined and cost-effective tooling development process.

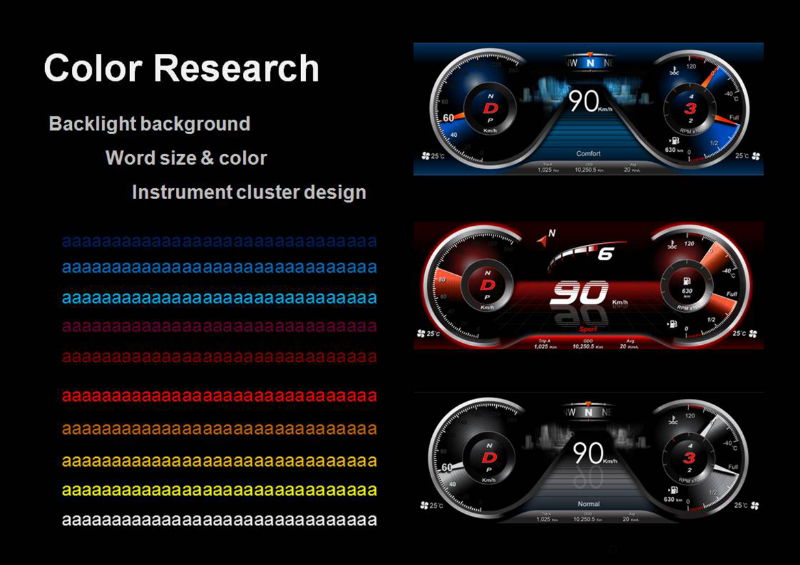

Industrial Design

Industrial Design Dept. located in Taipei office, where we have Mini Camera Studio, 3D Printer, various Color Chips and Lighting Booth with Painting Shop. It provides following services. Idea Sketch - Employed at a personal level to quickly externalize concepts by using simple line-work. Study Sketch - Used to investigate appearance, proportion and scale in greater detail than an Idea Sketch; Referential Study : Used to record images of products, objects, and any relevant observations for future reference or as a metaphor; Scenario Study: Describes interactions between user and product under appropriate contexts; Sketch Rendering: Generates clearly defined proposal by controlled sketching and use of color/tone to enhance details and reality.

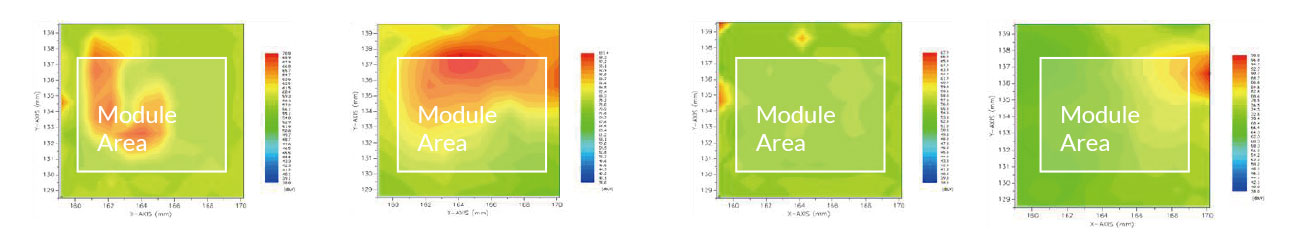

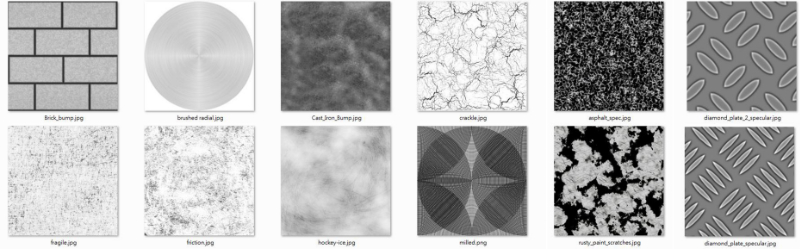

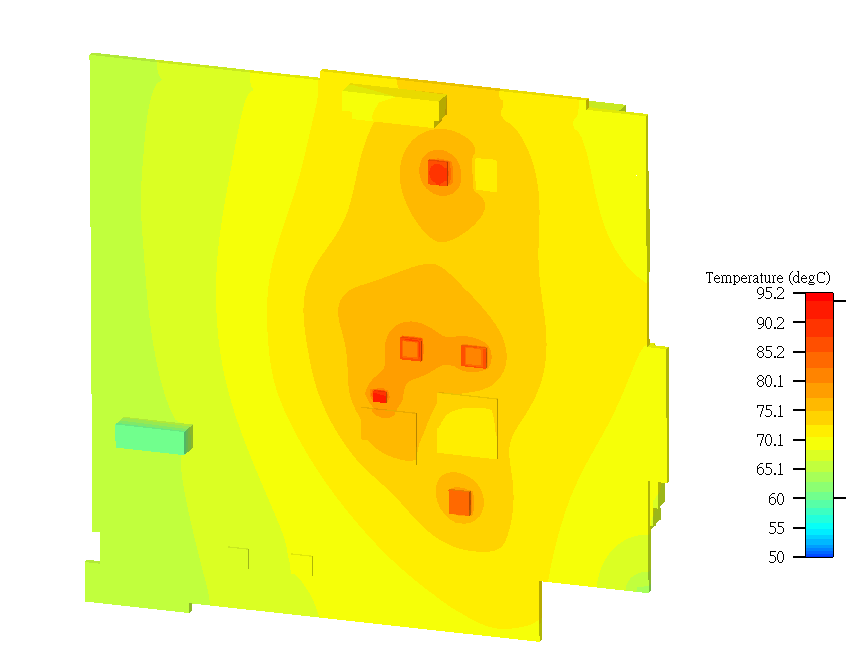

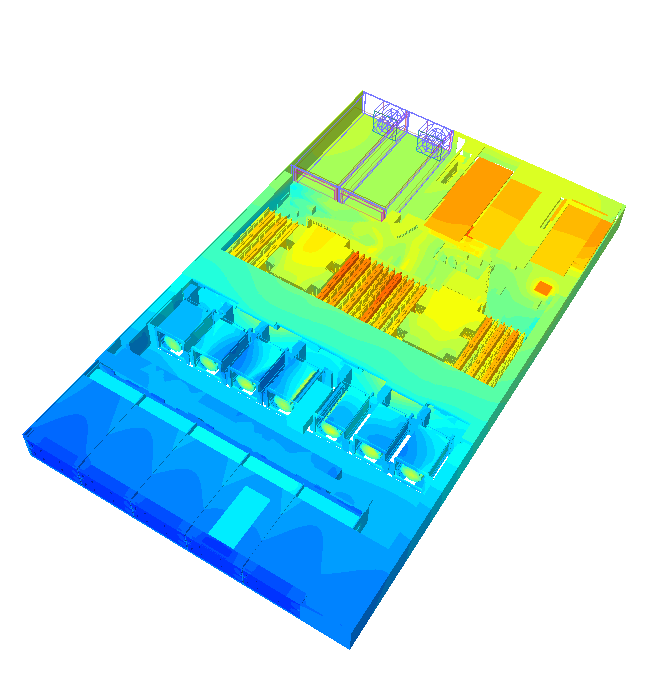

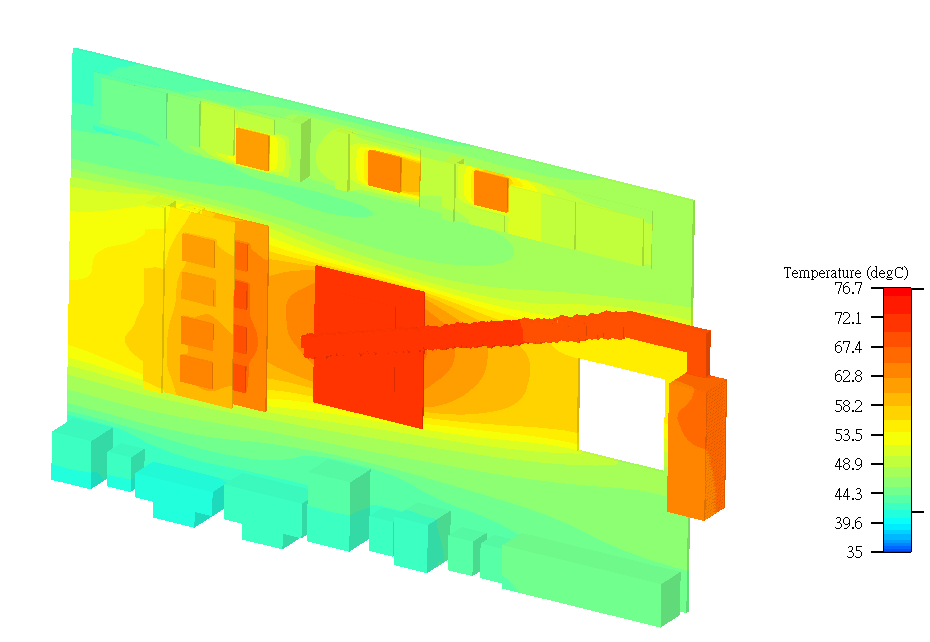

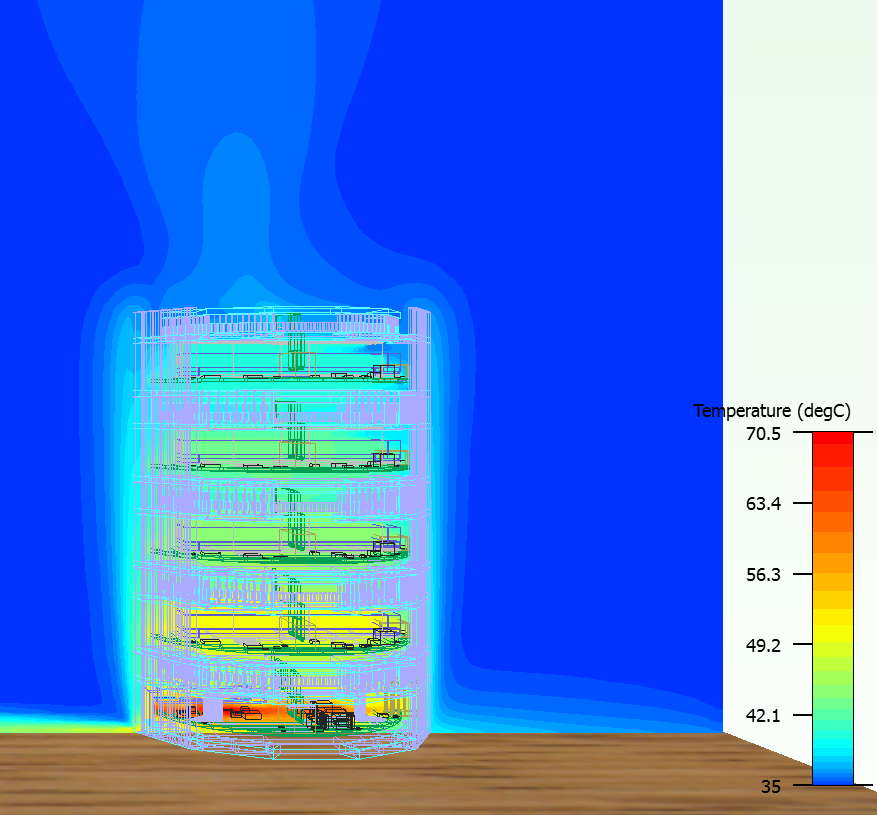

Design Simulation

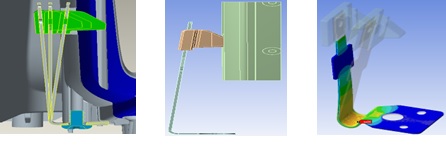

Design Simulation, also called Computer Aided Engineering (CAE), covers two sections which are thermal and structure stress. Simulation has become a key enabling factor for product development in the highly competitive electronic industry. CAE methods play a vital role in defining new product concepts from idea to empirical products. We utilize Flotherm for thermal simulation and ANSYS/Multiphysics & LS-DYNA for structure simulation where CAE methods are applied from the concept definition until product release to support concept finding and optimization in terms of material selection, durability and reliability.

Motion Simulation enables us to conduct dynamic characteristic, verify motion of a product under test condition in early stage, validate a substitute idea and hold a presentation of the product by associating all kinematic parts with each other. Thermal simulation provides benchmark of system and component competitiveness and performance. Through standardization of CAE process and clearly defined objectives in the simulation methodology, we can support database driven benchmarking and target value setting.

%20simulation_all.jpg)

%20simulation_all.jpg)